Lots and lots of work!

Lots and lots of work!

This past week has been day and night working on the Jeep. Any time not eating food or working has been spent working! So much to do, so little time… but some great progress! It’s been a lot of work for sure. The Grill is finished, and lots more parts are painted. I’ve also started to amass all the various bolts/screws/nuts/washers/etc I need for mounting everything on the Jeep.

The pioneer tools came in from Walck’s 4WD! But, as it seems lately, not without some issues. More on this later.

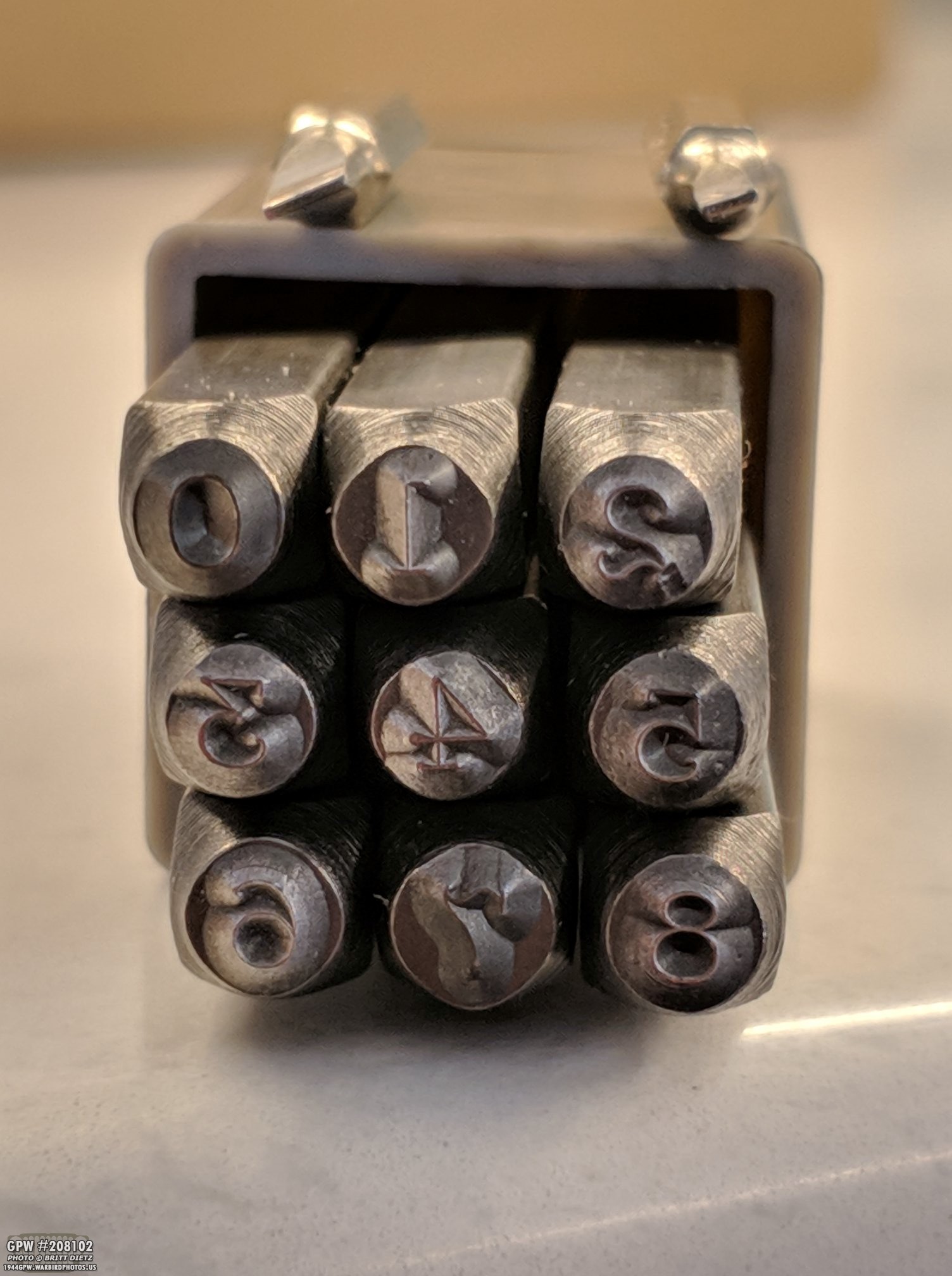

If you remember from my last update, I decided to stamp my own data plates. I lucked out and found a place online that sells ‘vintage typewriter’ font style punch stamps, which are 85% close to the font on my original plate. That number set shown here, plus two small flat head screwdriver bits were all I need! But first some practice…

Since I had accidentally bought the wrong data plates originally, I had a blank one to practice on, along with the backside of one of the unneeded plates. It took a lot of practice to get the right pressure of the hammer hit to make them look right. Too hard and it smuged or started to bring in a circle from the punch… too soft and you can’t read the numbers. After spending 20 minutes testing different methods, I took a deep breath and started work on the real plate…

Here’s the result. I think I could have probably done better, but it’s not bad. It matches up pretty good, and I even added some light ‘weathering’ to it to make the numbers stand out a little more. To make the ‘T’ in ‘1/4 T’ I used the number 1 and those two small flat head drill bits to make a custom T. Came out pretty good.

Next up was mounting the plates to the glove box! I had bought a special tool for just these types of rivets from a vintage card place online, and they worked well! Here’s the front and back after the rivets were squished in there! I nicked the front slightly when the punch I was using for the rivet shifted, whoops, so I’ll have to fix that. I also nicked the paint in the back a little, but that’s an easy fix compared to the front.

Back to the tools, I got the shovel and axe from Walck’s 4WD and immediatly set out to try and attach them to the MD Juan tub with the strap set from Ron Fitzpatrick Jeep Parts… but it was clear things didn’t fit right. It took about 30 minutes of fidgeting with them (the shovel might be slightly too small, and the head of the axe way too big), but I got them to fit in there with the straps! But… there’s another issue…

That darn interior green that’s almost a neon color. Yuck! So, I’ll have to paint the Axe and Shovel.

After masking off the wood and sanding that interior green paint, I hit them with the first coat of OD Green (33070). Already looking TONS better!

I also took the time to paint more items, which required me to set up the canopy again because we seem to have only days with heavy winds lately. 10×10 canopy and some tarps from Harbor Freight help out great (and shield me from the hot sun)

After the difficult process from the last update of tinning the top of the grill, it was time to fix the areas where the paint had bubbled from the torch heat. I hit them with some quick primer in the spots, and now a few days later I was able to paint them with OD Green again.

I also started the OD Green paint process of the driver’s seat since it’s been ready for some time! (note the color is off here because of the light coming through the tan canopy)

I also had to touch up a few spots on the driver’s side fender as I accidentally knicked it a few times the last few weeks while it was on the ground. Whoops.

I also added one more coat of paint (the final one) to the glove box doors and the front bumper. I still have to paint the bottom inside of the bumper again.

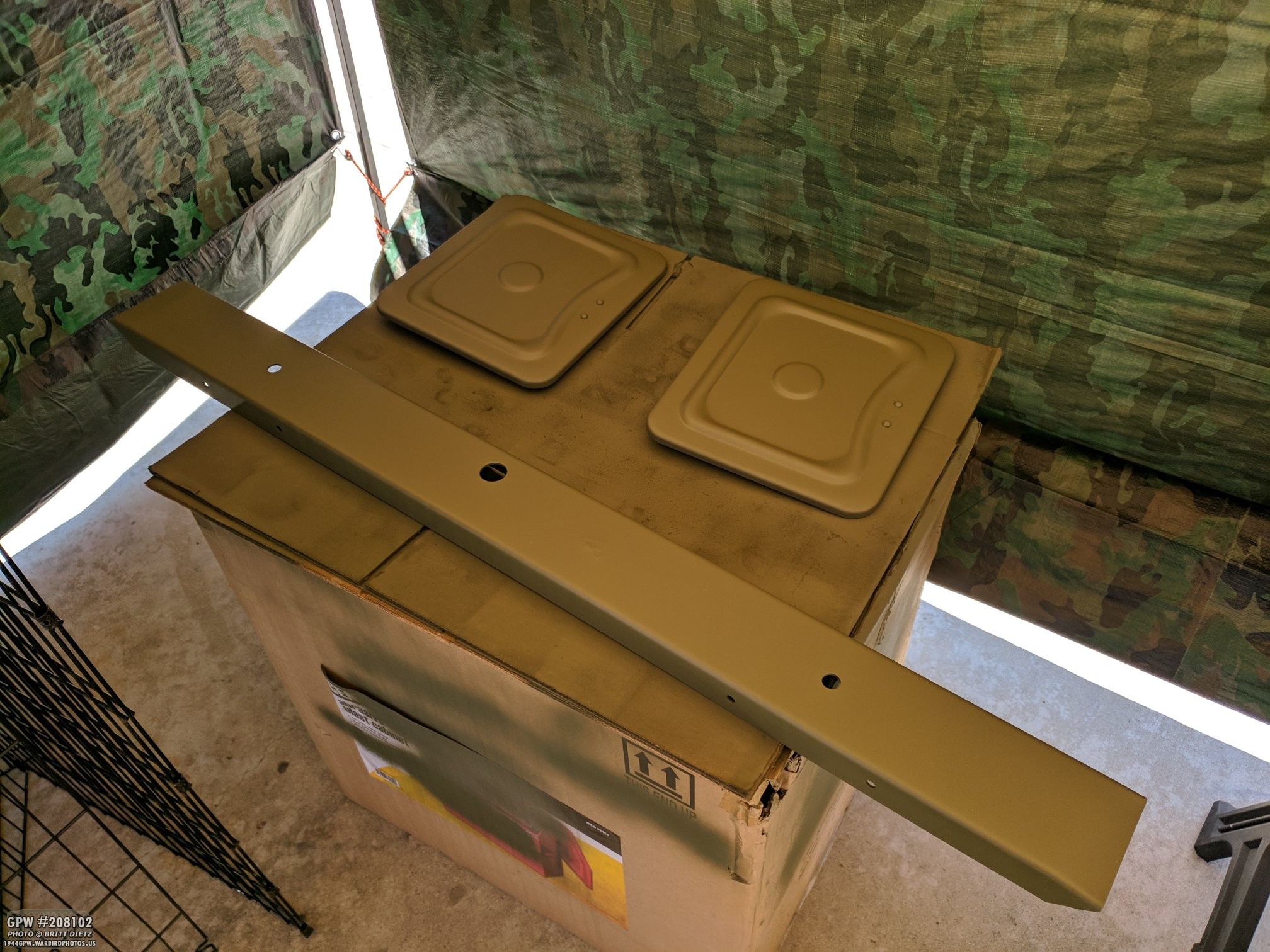

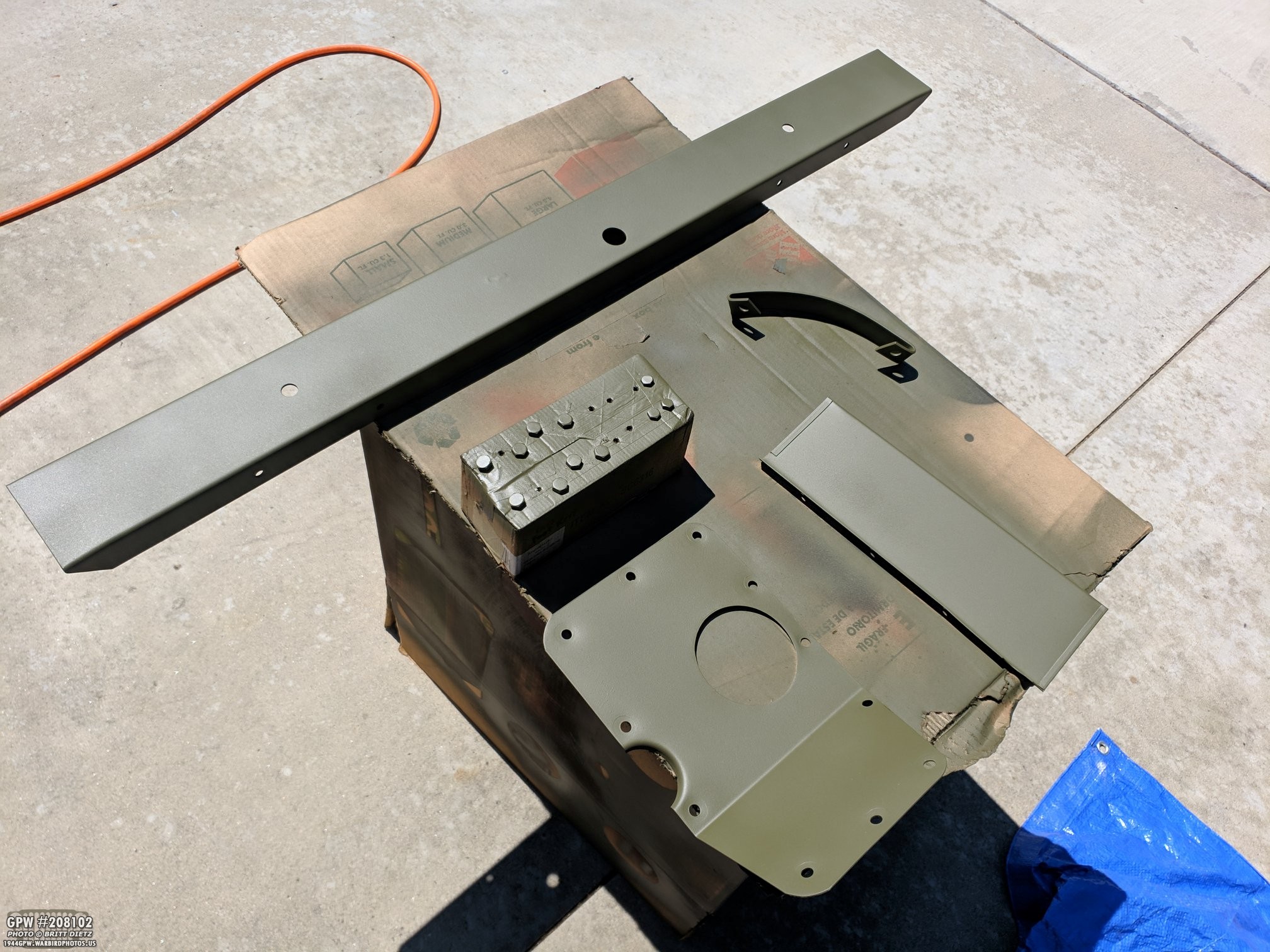

Finally, here’s the rest of the items painted that day including the final coat on the glove box (this was before I put the data plates on), the transmission cover panel, the trailer socket door, the gas can shield, the brake pedal, and a bunch of screws/bolts.

Jump to a few days later with some light winds, I was able to paint the bottom of the driver’s seat.

I decided to do one more coat on the front bumper, since it’l get a lot of abuse, along with the transmission cover panel. I also painted more bolts, the other side of the gas can shield, and touched up the shovel bracket where the shovel had scratched it a bit while I was trying to figure out how to install it.

I also put another coat on the footrests when I realized, after the last update, that test mounting them to the tub scratched them in a few little places. I also painted the shovel with a second coat, and fixed that knick on the front side of the glove box before masking the data plates off and hitting it with some paint where I had sanded the knick.

Now that the paint was all dry for the glove box doors, it was time to install the felt weatherseal liners! They came with 3M tape already attached, and broken into 4 sections for easier install.

All installed, and looking really nice! I bought museum quality tool box locks for the tub as the ones I had were slightly busted. They should arrive next week.

Now that the Grill was dry, it was time to start putting it all back together and finishing it for install. A LOT goes on the Grill, so it’s a large project on its own! Here I’ve reinstalled the two blackout marker lights and added star washers to them for better grounding.

Added the headlights back on with the new Ford F stamped hardware!

I then took the Grill and test mounted it to the Frame to make sure all still fits and figure out what bolts are best (3/8 if you’re curious). It actually looked like a Jeep again for a few minutes!

Here you can see the tinned area on one of the top of the headlights and also the Ford F stamped hardware I got. Technically, just about all bolts on the GPW should have F stamps, but I’m not going that far since that is crazy expensive to do. (Note – At the time I didn’t realize these bolts should be upsidedown with the nuts on top, this will be corrected in a later update)

Removing the Grill from the frame, it was time to install the welting on the outer top edge. This welting is where the hood will rest. It’s also a collossal pain in the you know what to install because it requires split rivets. Here I’ve got two installed and, another spot where there was tinning, I put the small bond strap ground wire. That would touch two unpainted tinned spots on the inside of the hood to help for better radio signal suppression.

Almost done with the top, and I heavily DISLIKED doing this. It was incredibly time consuming as those darn rivets did not want to split and I had no special tools to do it. I had to come up with something on my own…

Which was this redneck looking DIY for splitting rivets flat. It’s a pipe wrench plier with two small bolt nuts attached to each side covered with duct tape. That along with pliers, a screwdriver, and a small strip of leather to help protect the paint job and I was able to slowly bend them flat.

Doing the curves were a bit easier as they had less of a lip and were more flat. This shot also shows off the crazy double clips that hold the two headlight wires together. There was quite a bit of research that went into making these go the correct way!

All done with the darn welting! I hope to never have to do that again, or if I do to get one of those expensive split rivet pliers.

Next up was the radiator air deflector felt strips. These were stapled to the grill to help force air coming through the grill to go into the radiator and not escape around the sides of it. The Jeep came with two kits of this felt and three bags of staples… but the staples were all wrong in all three bags! They were too wide and too far apart to fit in the original holes (and I didn’t want to drill new ones)… so I decided to make my own.

Using rigid wire, two nails, and a lot of patence, I was able to construct staples that perfectly went in the original holes and held the felt well. Here’s the outside of the top as it was being worked on.

Looking on the other side, you wouldn’t know those are not real staples! Looks legit, and uses the original holes. Win win in my book, even if it took a lot more time to do!

The Grill is ALL finished and ready for final reinstall on the Jeep! Can’t wait to do that!

Back to the Tub, if you remember from last week’s update, there was major issues with the MD Juan tub mounting on the original frame. With my friend Andrew over at the house, we spent quite some time trying to figure out how to make it work. We figured out that instead of trying to align the tub from the back bumper mounts, align it up with the only other mounting spot that’s drilled… the capture nut hole next to the gas tank sump.

After carefully getting that bolt in the capture nut, the rest of the tub mostly started to line up, enough that we were able to make the holes I’d need to drill for mounting! So that’s good news! I will still need to fix the back bumper’s bend in order to get those holes to line up.

Moving on to the gas tank, I still needed to drill the hole in the floor for where the fuel lines come up to the bottom of the gas tank (shown here). One trick I had read was to put some black paint on where the fuel tank would connect to the fuel lines and put the tank back into the Jeep. Pushing on the tank will mark on the tub where that hole should be.

Taking the tank back out, BINGO! It worked! That little half circle is the exact spot I’ll need to drill.

It needs to be a massive 1 and a 1/2 inch hole, however, so I started with a smaller drill bit and had to go about trying to figure out how to drill a hole that size. The solution was one of those drill cup bits that have the narly looking teeth. Sadly, because I already drilled a hole the largest drill bit size I could fit in the drill, that meant that the cup slid around as I cut the larger hole… doh!

Amazingly, the cup devoured through the sheet metal in seconds. The result even with the shifting… not too bad! It’s close enough!

Next up, I decided to test mount the driver’s seat to the two capture nuts that were already added on the tub. If you remember from the last update, it ‘almost’ fit… but I found that the legs of the drivers seat have a little give, and with that they bolted down nice and tightly! Yay for something working without any modifications!

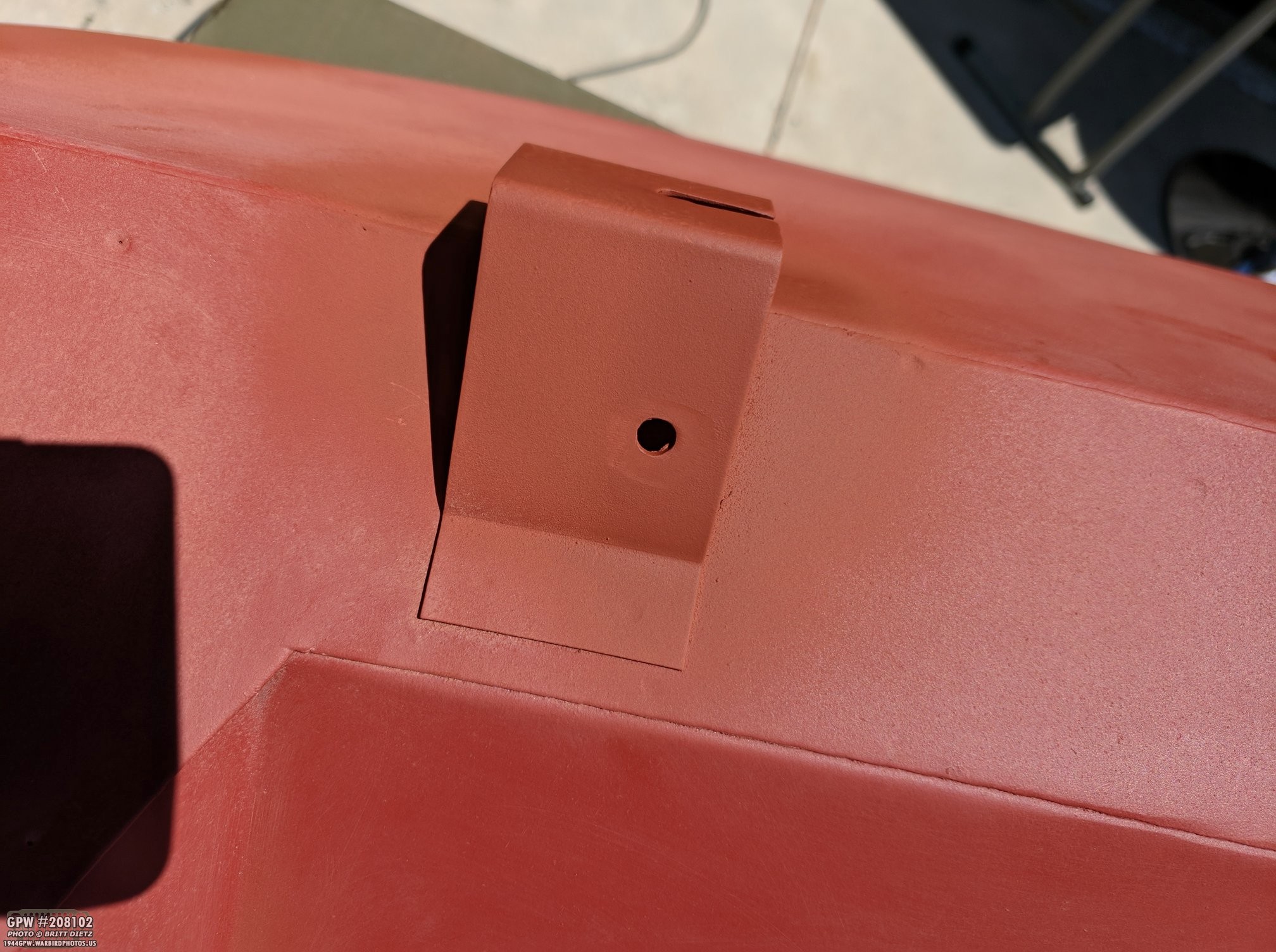

The passenger seat, however, was a different story. Those two holes I would have to drill myself. The seat legs attach to two L brackets. This allows the seat to rotate up and forwards to store things under the seat (like the canvas top). Here I’ve used the measurements from my original tub to get the spots where the L brackets would go. It was pretty close, just had to adjust the outter one a little bit further out to get both of the L brackets on the outside of the seat legs.

After drilling and mouting, it was a pretty good fit! Looks to be about as close as I can get it, if not pretty perfect!

Looking under the tub, the left side bolt went through the direct middle of a hat channel (on my original tub it looks like there was a capture nut in the channel there), and the other went through the flange of a support on the bottom. It looks like there was an attempt at one time for them to drill the passenger seat holes… glad they didn’t, look how far off it would have been!

I also started to remove all the hardware from the side of the tub for painting and fixing any holes that need either 1) red oxide primer or 2) some JB Weld steep to close up also ‘whoops’ elongated holes. Here’s a before and after. I’ll need to sand smooth the JB Weld once dry.

I got a large bag of bolts from Bolt Depot, which if you need special bolts, regular bolts, screws, really any sort of hardware… us boltdepot.com! They have great prices, have every bolt imaginable, and come in amazing little detailed and labelled bags! These will go to all sorts of things like the fire extinguisher bracket, junction blocks, clips for the electrical system, and so much more.

I got much better brass nuts for the exhaust manifold since the ones that came with the kit were regular steel. Looks better with the touch of gold!

And I started several trips to The Home Depot to get all the tons and tons of bolts I need for various things on the Jeep. If the bolts that I have are not original with F stamps, I’m, probably going to replace them with brand new stronger ones.

Here’s an example of the one of the body mounting bolts. 3/8 and 2 inches long with teeth lock washers, washers, and a nut. I’ll ground the heads flat removing any of the company info.

Lots and lots of bolts. As I get things all sorted, I’ll be painting them with primer and then OD Green before reinstallation.

After priming, I’ll hit them with OD Green, which will get a little messed up when installing them and applying tension, so I’ll end up painting them a final time after installation.

I test fitted the large junction block on the firewall… didn’t quite fit at first. So I slotted the screw holes just a tad, and it fit just perfect!

For the sake of time trying to get the Jeep done by the June 27th event at Lyon Air Museum… I decided to go ahead and use the reproduction passenger fender on the Jeep. The original passenger fender will require a lot more welding than I thought was needed, so it’ll take some time to repair, which I won’t have between now and the 27th. It’s just easier to sand the repro fender, touch up the primer, and paint it OD Green.

I did notice that the hole for the headlight swivel bracket wasn’t drilled, so using my original fender I got the exact location lined up and drilled it.

Finally, here’s the repro fender with the first coat of paint, what a difference OD Green makes! I will end up fixing up the right fender and replacing the repro one with the original once it’s finished. Then I’ll sell off both repro fenders.

That’s it for now, some big updates coming next week! Till then!