Second GPW Rear Axle… Does it make a sound?

Second GPW Rear Axle… Does it make a sound?

Finally, after about three weeks of work I’ve finished the SECOND GPW wartime axle… but the big question is: Does the mysterious clackity sound from the first GPW axle go away? Find out in this update along with some video links from the new GoPro!

Here she is, looking all nice and pretty after that test drive… but I’m going to hold you in suspense until after I finish the axle rebuild!

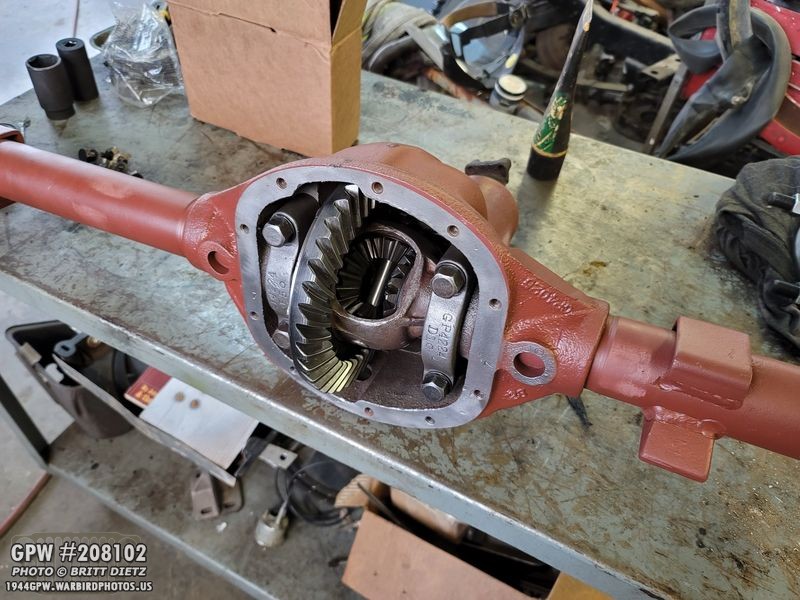

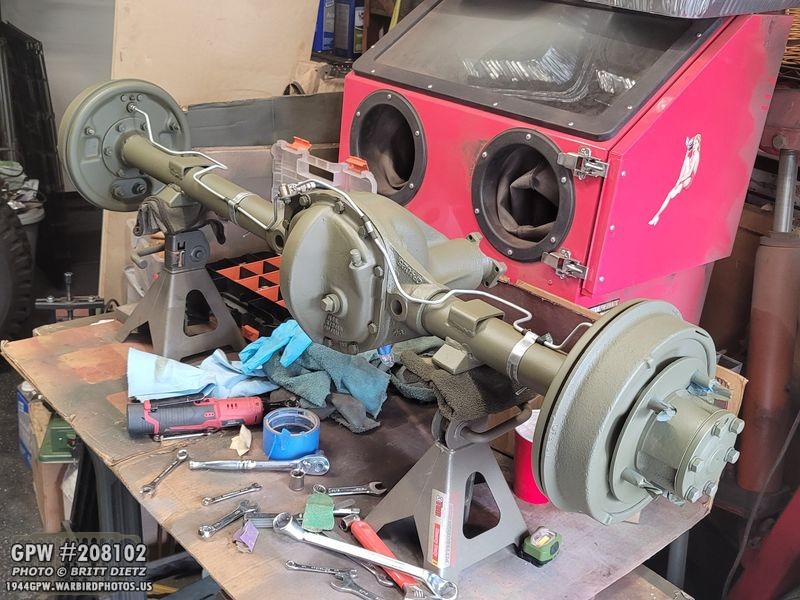

At this point, I think almost everyone knows the story of what’s happening with the Jeep, but just in case the quick recap… My Jeep had CJ axles when I got it. I got a pair of WW2 GPW axles that I restored over a year and replaced the CJ axles with in December. That’s when a mysterious ‘clackity’ sound appeared from the rear axle. After spending several months with many experts trying to figure out what it was, I eventually gave up and found a second WW2 GPW axle to replace the other one, which is what I’ve been working on the last few weeks. Here’s the second rear GPW axle after setting the ring and pinion last week.

Last week I talked about the grease test on the ring to make sure the Pinion depth is set correctly. It’s a tough project for sure, but that was the major holdup on continuing forward with the Jeep.

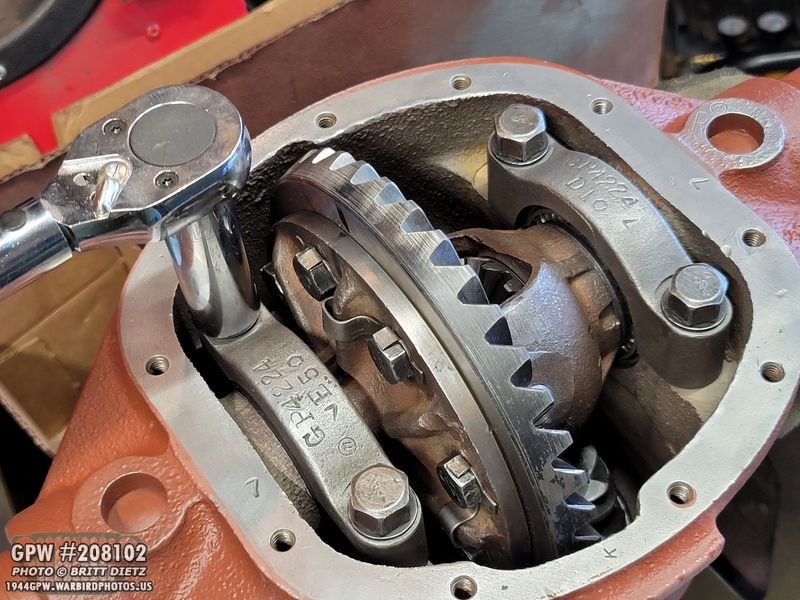

After getting the axle back home after setting the ring and pinion, I still had things to do. I had to set the pinion bearing distance shims (that rest against the spacer). After finishing that, I could then put the carrier (which we already set up with the correct shims) and torque down the bearing caps.

With the pinion finally set I could add the oil seal to the back of the axle. Don’t forget to add some grease to the rubber so the yoke doesn’t tear it up.

Now it can be fitted onto the rear of the axle. I used a punch and a very large socket to get it on.

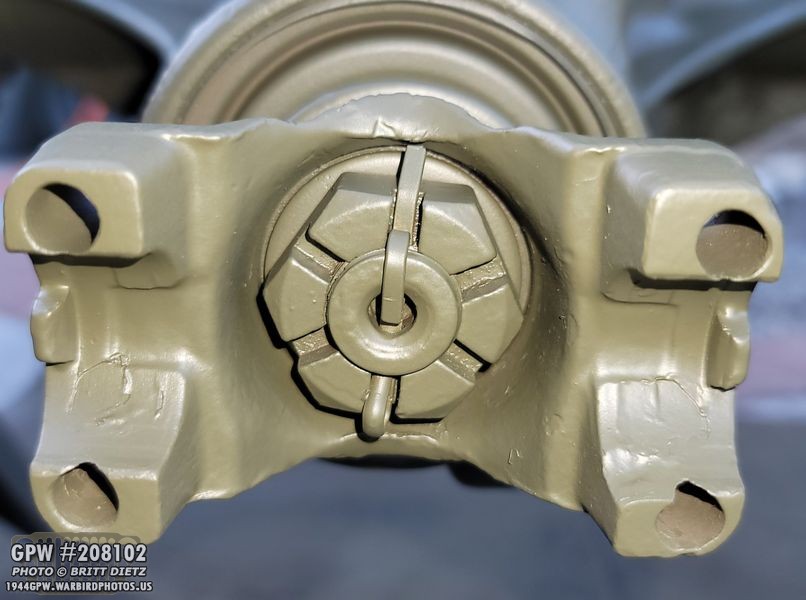

Oil seal installed, yoke added, and the castle nut torqued down! Just needs a cotter pin.

Since I’m using the cover from the first rear GPW axle (and it’s already painted OD Green), I put a spare CJ cover I had on with some spare bolts so I could touch up the red oxide primer paint.

Before doing that, I put some black RTV in the holes where the carrier bearing cap screws go through the housing. I’ve been told it’s a good practice as those bolts can leak oil at times.

Once the RTV dried, it was time for paint!

All primed and ready for that glorious 33070 OD Green.

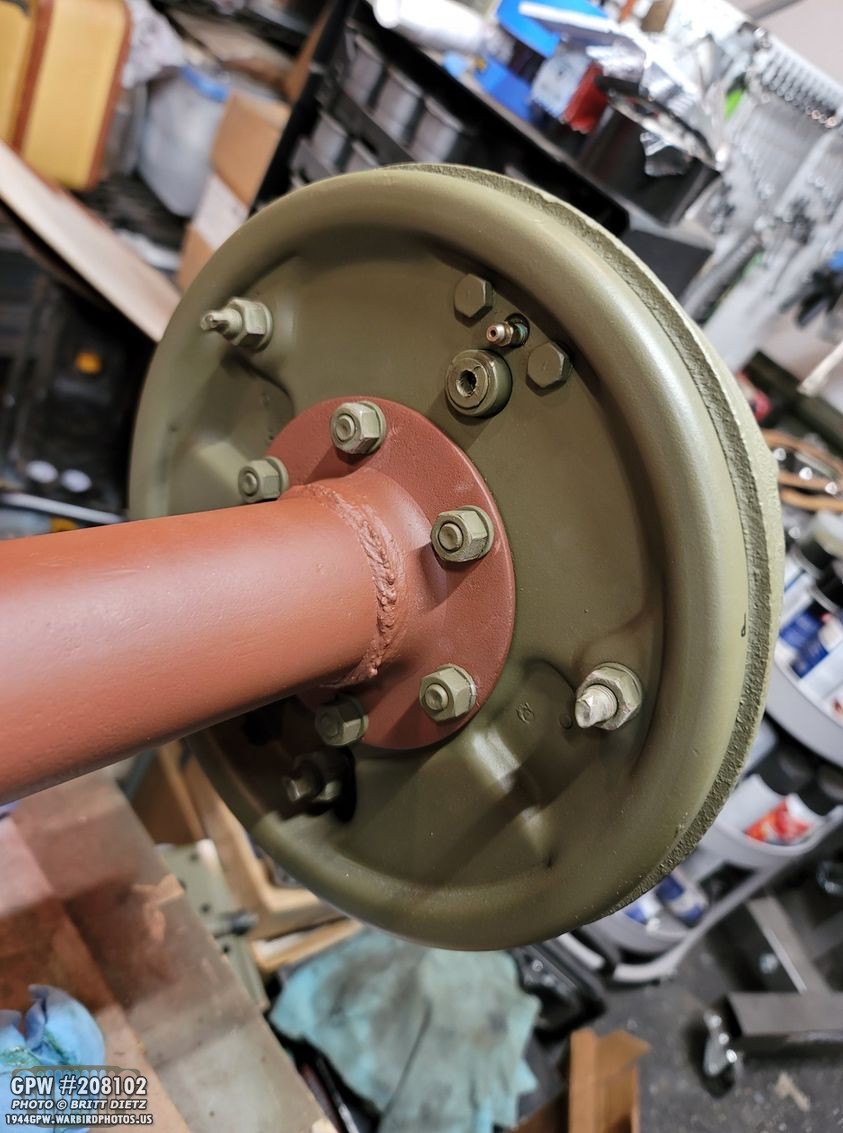

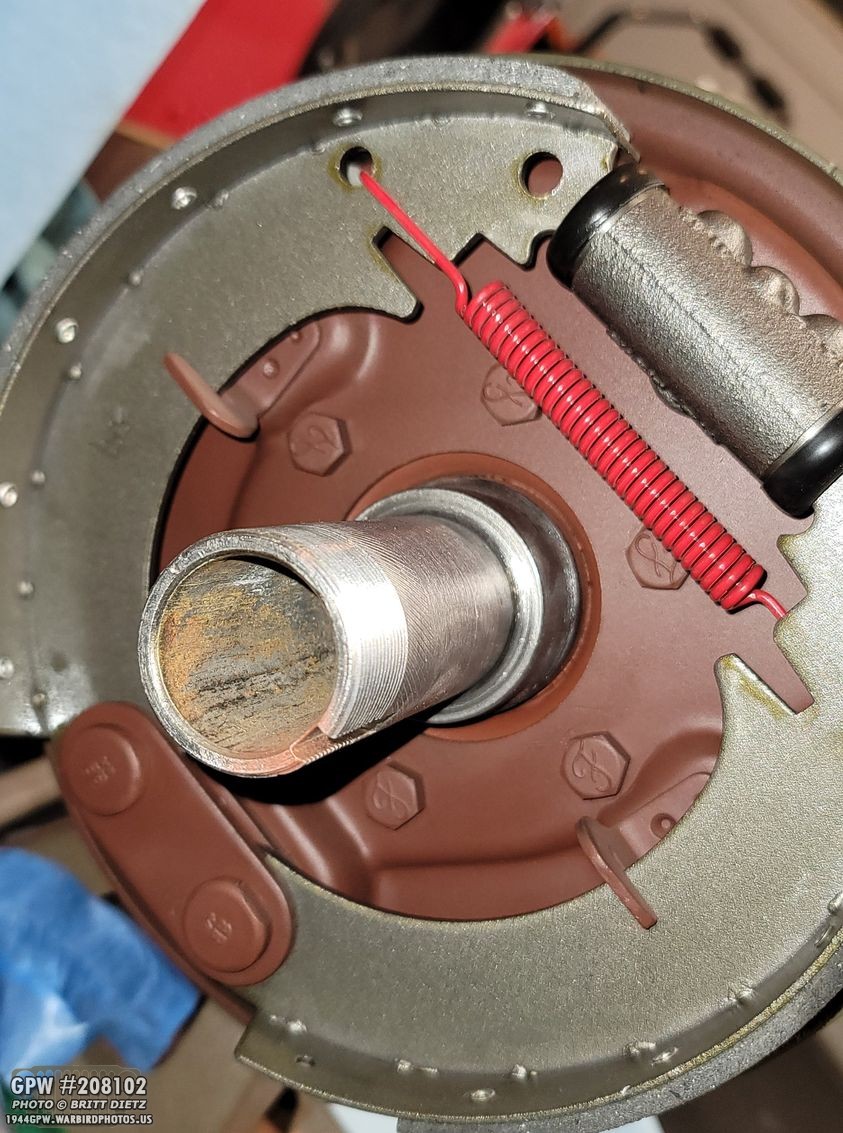

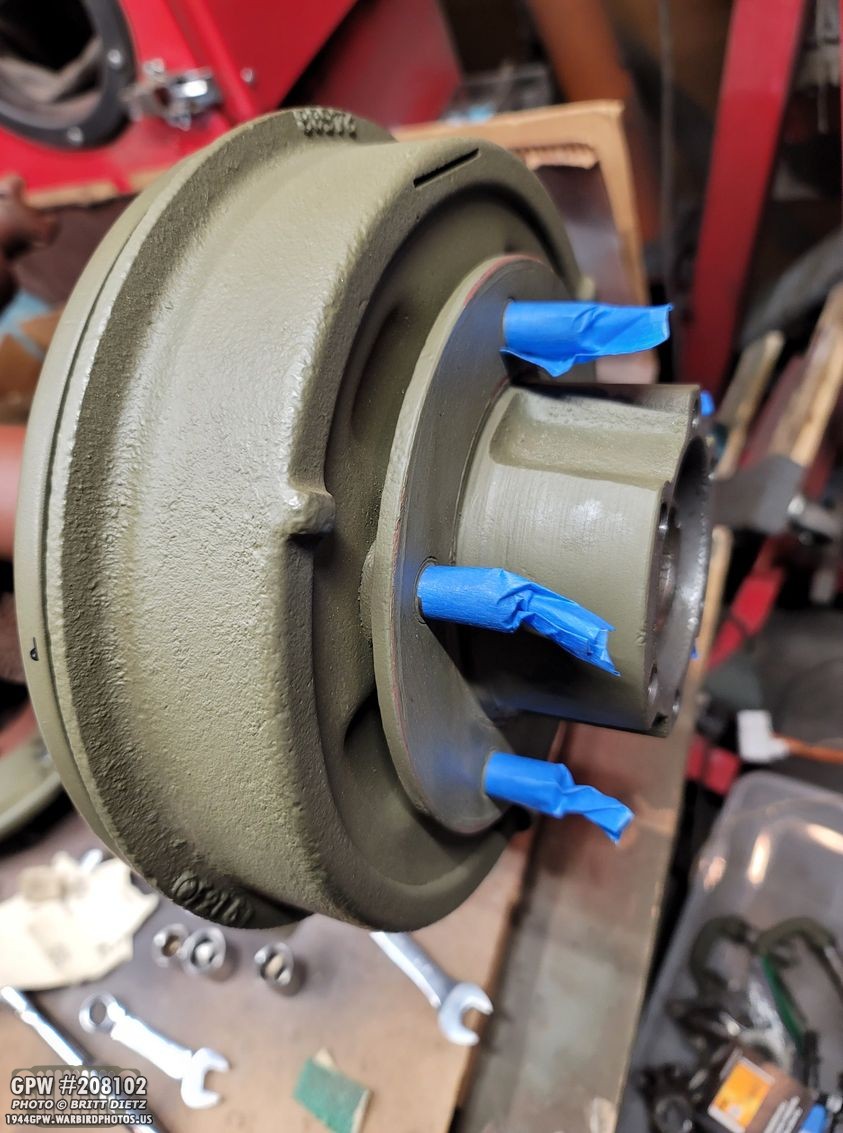

Since the OD Green was the next step, I had to go ahead and get the rest of the axle on. So, first up is the brake plates. The plates and drums are from the first axle.

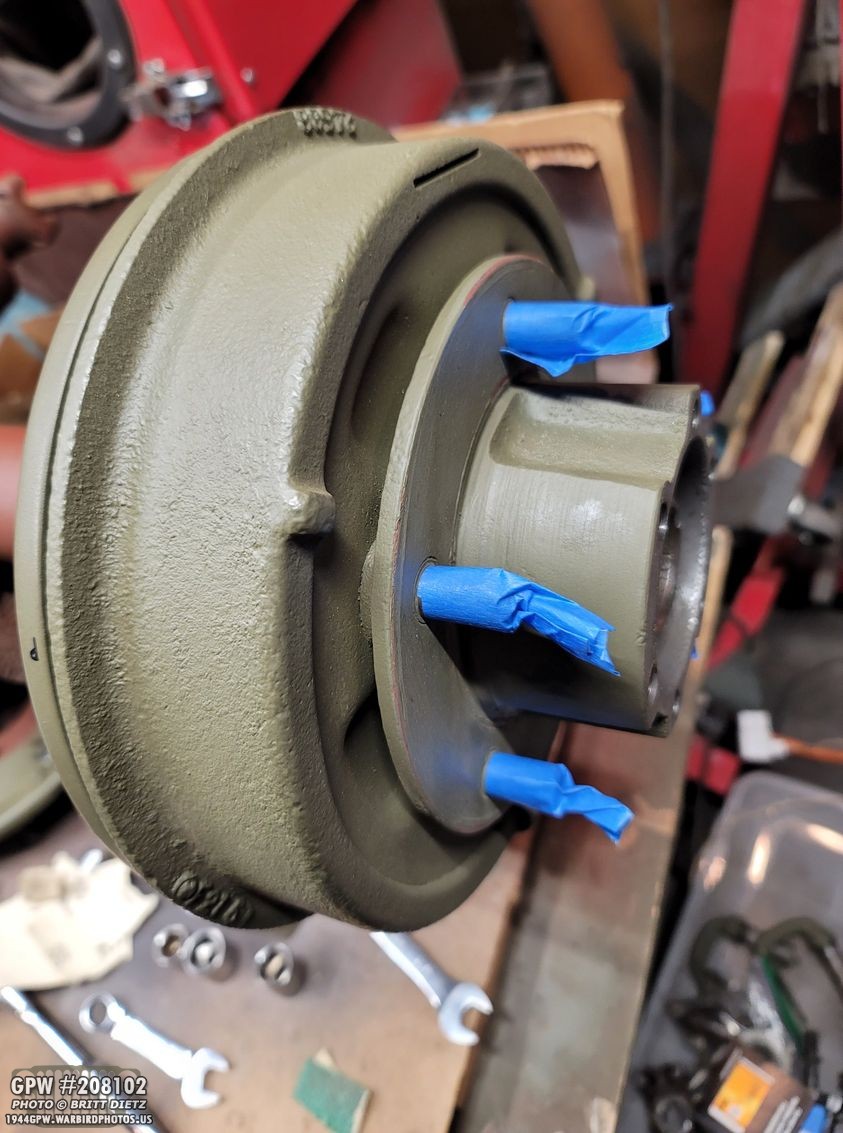

Then the drum was added.

I’m also reusing the drum bearings/races since they are brand new from December when I restored the first rear axle.

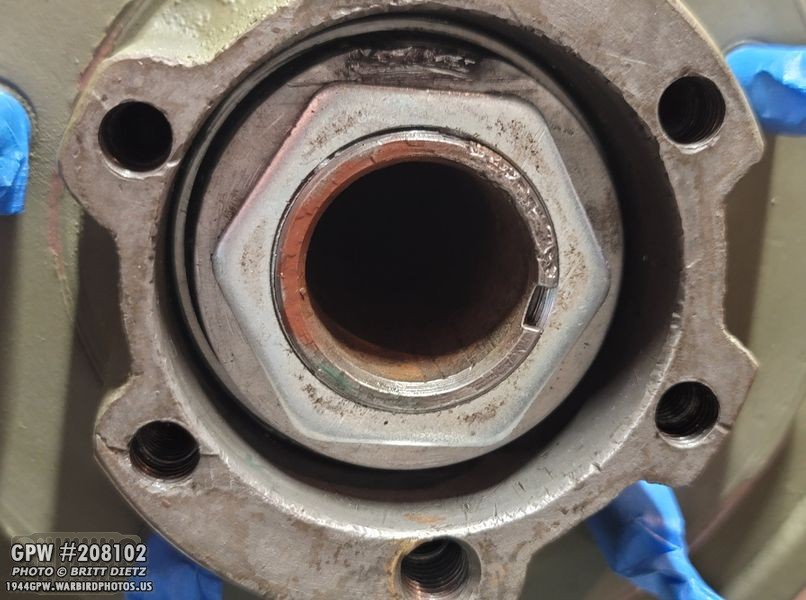

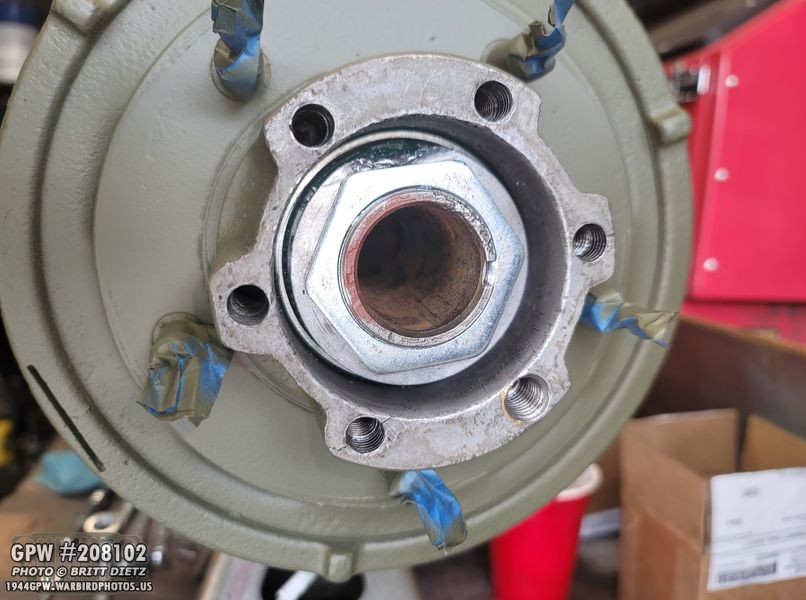

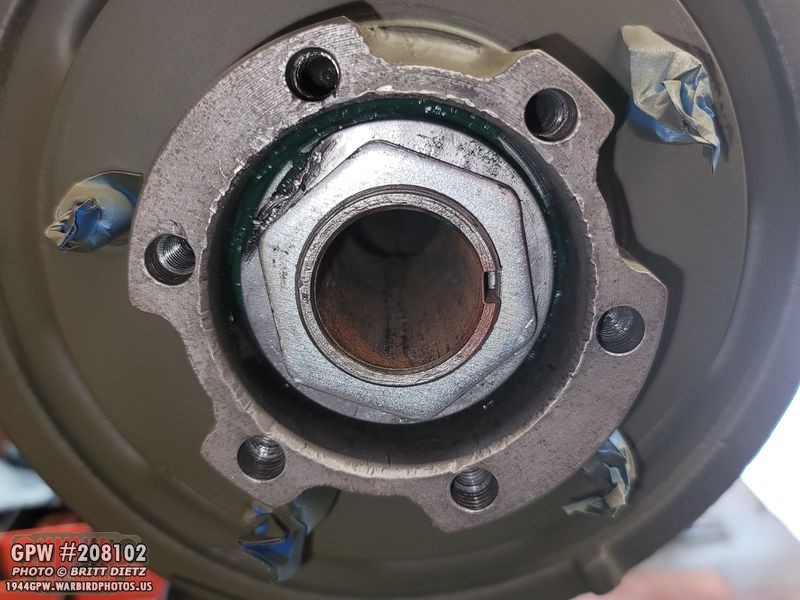

I’ll go through the rest of the process quickly… after the bearing is the first tabbed washer.

Then the first axle nut. I went and got brand new ones of these.

The large WW2 axle nut socket to the rescue again! Makes putting on those axle drum nuts SUPER easy, and gets them nice and tight.

After the first nut is tight, which pushes in the bearing, the next is the large tabbed washer. As you can see, I’m using the ones from the other axle as well. I realized, these were new until I peened over the edge to lock the final nut in place, but that peened section is actually really strong still.

Finally, the last nut tightened.

Then I moved to the other side.

One last look at the brake setup and original F bolts before the drum goes on.

Same process as the other side… thin washer, nut, thick washer (with the tab going inwards towards the housing), and the final nut.

And one last look at the ring and pinion before I seal it up. Remember, this is a totally different housing, carrier, ring, and pinion. Brand new Timken bearings as well.

This is my first ‘home-made’ gasket for the Jeep using photoshop and the Cricut Explore Air 2 cutting machine! Fit perfectly. Here the first axle’s cover is going on with the original bolts.

Bolts on along with the axle ratio tag (bottom right, the one bolt that looks like it’s black). Ready for OD Green!

It was a really hot day that day, which was great luck for me. Ron Fitzpatrick Jeep Parts 33070 OD Green in the gallon form mixed with Xelene thinner works wonders and dries in just a few minutes. I was able to put three good coats on throughout a 5 hour period.

I also added the cotter pin to the castle nut on the yoke before painting.

I put some thread sealer on the axle drain plug and got that all tightened up.

With it all painted and dry, I went ahead and peened down the large washer again locking the nut in place so it can’t spin off.

Same with the other side.

Now time to put the axle shafts in! Put a bit of grease on the end so it rotates freely (without a squeak as well) on the inner oil seals.

Coming together! Now time for the brake lines (also from the first axle).

Brand lines installed! Still need to add the straps.

Before I could lock down the axle shafts, however, I will need to adjust the brakes. I would have used my own homemade gaskets from the Cricut for the axle shafts, but I managed to somehow buy 3 extras for some reason back when I was doing the first GPW rear axle last year.

I have them all ready to go in photoshop (along with most of the other paper gaskets on the Jeep) for the Cricut machine in the future if needed. It’ll be nice to make a gasket on the spot and not have to wait for one (though, the 2-day shipping from Ron Fitzpatrick Jeep Parts makes it super easy if I do need something quick!)

ALL DONE! The second rear GPW axke is finished. WHEW!

Moving back to the housing, I still needed to paint the heads of the cover bolts. So I covered up the brake lines and hit it with 33070.

Time to adjust the brakes! Even though they were already adjusted on the first GPW rear axle, they ended up being off once I put them on this axle. So a ‘minor’ adjusting was needed. I won’t be doing a complete tutorial on adjusting the brakes because I’ve done that in the past. You can see that entire tutorial here: https://www.1944gpw.warbirdphotos.us/blog/rear-axle-work-part-2/

It took a bit of work adjusting the brakes. I used a combination of a feeler gauge (to start and get it ‘close’), then I finished with the ‘minor adjustment’ method where you turn the adjustor screws until you hear the brake pads contacting the drum, then turn the adjustor screws the opposite way incredibly slowly until the contact stops.

And with the brakes adjusted… the SECOND rear GPW axle is complete!

Here’s a look at the first GPW rear axle, which has been gutted. I didn’t use the carrier, ring, and pinion from it, those are sitting off camera. I might sell this axle ‘as is’ if someone wants to try and see if there is something wrong with it (maybe or maybe not). It’s an early war GPW axle.

For a brief moment, GPW rear axle #1 and #2 sat next to eachother as I prepped the Jeep for the new one.

When I originally installed GPW rear axle #1, I went through the entire reinstallation process step by step, so I’m going to, again, fly through this. This time, however, I used the transmission jack to help me raise up the axle and keep it in place. SUPER helpful! Here I’m about to install the shackle on the right spring.

Springs reinstalled, the axle is not a ‘part’ of the Jeep (well, technically just sitting on top of the springs).

Time for the U-bolts. If you remember when I did this the first time, things didn’t go so well when I found the leaf plates (not on yet) were bending when torquing the u-bolt nuts. I had to go to Walck’s 4WD to get the plates as their plates were thick enough to withstand the torquing.

Thankfully, those same plates worked a second time without a hitch. Nice and torqued!

Same with the other side. Now the axle truly is a part of the Jeep.

I was very happy to see the u-bolts were resting against the spacer quite nicely.

I compressed the springs upwards to the frame using a ratchet strap which allowed me to fit on the shocks. I was quite surprised to find the cotter pin went in super easy this time. Last time it was a huge struggle. I was quite proud of myself until I realized what I did wrong. Want to take a guess?

I forgot the dang end washer. DOH! So I had to remove the cotter pin and do it again. I remembered from last time that I had to install the cotter pins on the lower rear shocks upsidedown in order to get them to work. So, I ended up having to do that again. Shouldn’t make any difference, but I was bummed since I was so proud I thought I had it easy this time!

Finally, I put on the combat rims with the Firestone tires and torqued down the lug nuts.

Axle is installed! Just to reattach some things now.

First is to reattach the brake lines from the long hard line to the axle flexible line. Don’t forget the hose retainer clip! (this one is an original)

Now I could go ahead and get the Jeep off the jacks. The trusty Harbor Freight crane to the rescue again! It’s great to lift up the Jeep and not need a floor jack.

Back on the ground. Getting closer! Just needing to reattach the driveshaft, add oil to the axle, and bleed the brakes!

I ended up calling it a night that day but was excited to have completely finished and installed the axle in one day.

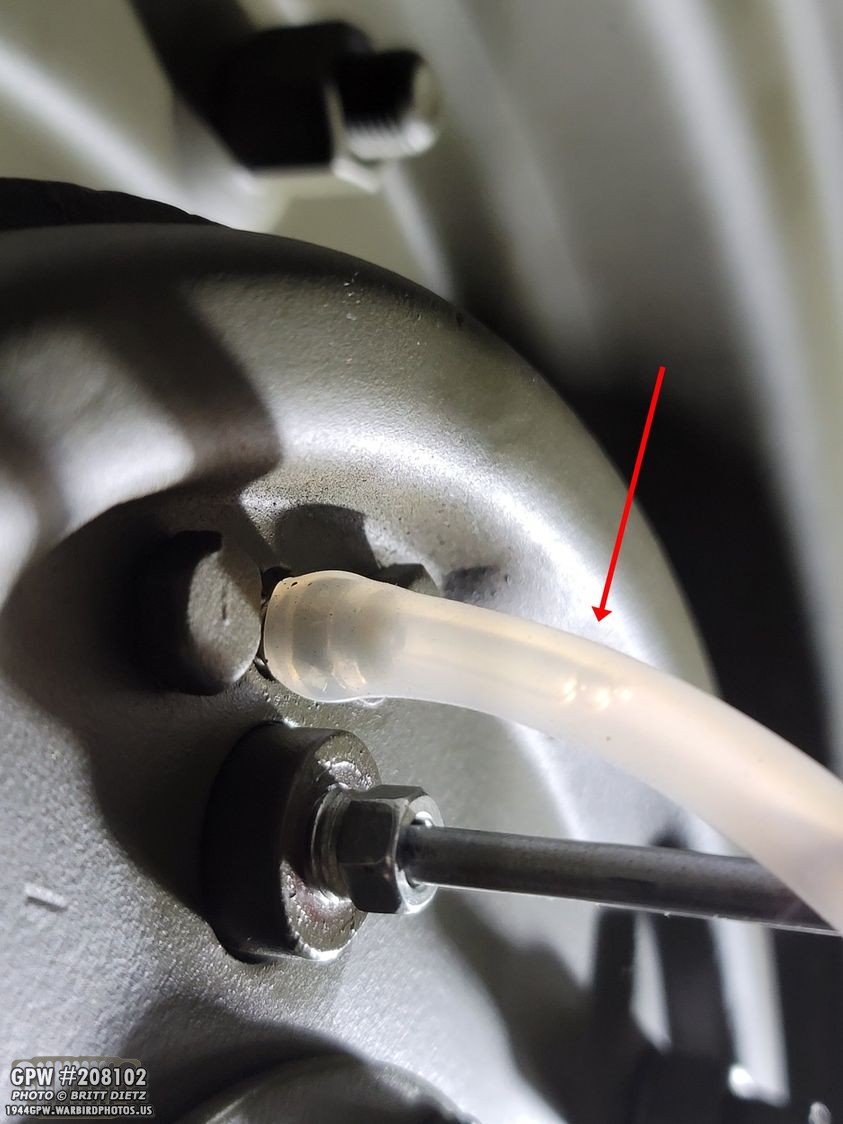

Next day I bled the brakes with my girlfriend’s help. Since we’d done this two times before, she knew the drill helping me to refill the master cylinder with brake fluid, and then sitting in the Jeep tapping on the brake pedal as I watched for bubbles with the brake bleeding valve open.

Here’s an example of the bubbles from the air that had gotten in from disconnecting the flex line from the main hard line. You can see an entire tutorial on how to bleed the brakes here: https://www.1944gpw.warbirdphotos.us/blog/drag-links-wheel-alignment-brake-bleeding/

I only needed to bleed the rear two brakes since the only line disconnection was from that long hard line to the flexible line. Since the flexible line is higher in the air than the master cylinder, the air would not go back into the hard-line. After the rear two were bled, I topped off the brake fluid in the master cylinder (pictured here through the maintenance hole in the body tub) and put the cover back on the hole.

Next up, I did the slow process of adding oil to the rear axle. I used gravity (and a ton of small pours of oil). Once it started to drip out the fill hole, I knew it was full.

Lastly, I installed the rear drive shaft, now straightened! It also has a brand new universal joint on the axle end with new u-bolts.

I then topped off the grease on the driveshaft (which, I didn’t realize the driveshaft place had JAMMED the grease in there, so I was actually adding more grease when it didn’t need it. Doh. What ended up happening during the test drive was the grease started oozing out of the driveshaft in various spots flinging it all over underneath the Jeep. UGH.

Anyway, with the driveshaft installed… she’s READY for action. I was nervous that night, since I’d be doing the test drive the next day in the sunlight. Nervous that all my hard work with this second axle would be worth it. But I felt like there was a good chance that I’d be super happy with a ‘non-clackity-jeep’ tomorrow.

So the next day, I hopped in the Jeep… rolled her down the driveway, started her up (after a 3 week slumber), backed her into the street, and popped into 1st gear. Moment of truth! And the verdict is…. clackity, clackity, clackity, clackity. I just couldn’t believe it. The clackity was STILL there. WHAAAAAT? And, it still sounded like it was coming from the rear of the Jeep.

I drove it over to the local park and just sat there in the Jeep for a while in disbelief. I immediately called Roger Smith, who I got the axle from and has been helping me with this mysterious sound. He was just as shocked as I was. I had the GoPro mounted under the Jeep, so after talking with him I came home and checked it out. The good news: The driveshaft is not perfectly straight. YAY! But the GoPro confirmed that the clackity sound was still coming from the rear area.

So, Roger thought, maybe it’s a problem with a rear wheel, so he said I should rotate the wheels. As I rotate them, he said I should deflate them, check the torque on the combat rims, reinflate them, and then rotate the front ones to the back and the back to the front. This took several hours to do as I had to get the Jeep totally jacked up (I used the crane to hold up the front with jacks as a failsafe, then the back was held up with jacks).

I had to get some photos of the Jeep without wheels!

I originally started with my special air tool for inflating tires. It has a special relief button that will let the air in the tire escape. This was taking far too long, so I decided I’d only use it to refill the air (it fills fast).

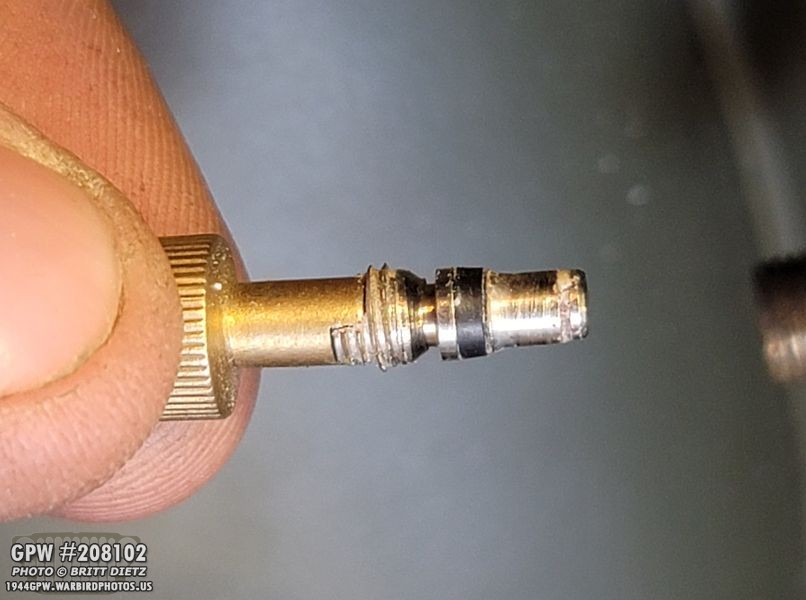

I did something I’ve never done before, and used the Schraeder screw-type valve caps to actually remove the valve from the tire tube! I unscrewed them off the valve, rotated the cap around, and then unscrewed the valve. Worked perfectly, as you can see here. This released the air much faster (just be sure to hold onto that cap as the valve will want to shoot out!)

With the combat rims all retorqued and the air back in the tires, it was time for reinstall.

Another hour later, all tires have been installed. After I took the Jeep off the jacks and let down the front with the crane, I finished torquing all the lug nuts. Time for another test drive before it gets too dark… crossing fingers, I hopped into the Jeep and took off.

Clackity, clackity, clackity, clackity. UGGGGGGH!

As I drove the Jeep back into the garage, you can imagine my frustration at this. All this work I’ve done the last few weeks and money… and it’s still there. No change in pitch or frequency from the first axle, but perhaps a little bit louder. So, what now?

On Wednesday, I decided to do a series of identical short drives around the neighborhood with the GoPro mounted in four different spots facing the four different wheels. This would allow me to pinpoint, without a doubt, if the sound is coming from the rear axle for sure. Keep in mind, I was already 95% sure due to previous times I mounted the GoPro under the Jeep in different locations (under the e-brake), under the middle crossmember, above the rear axle, etc). Here’s a look at the four spots on this map where I’d be mounting the GoPro on the frame.

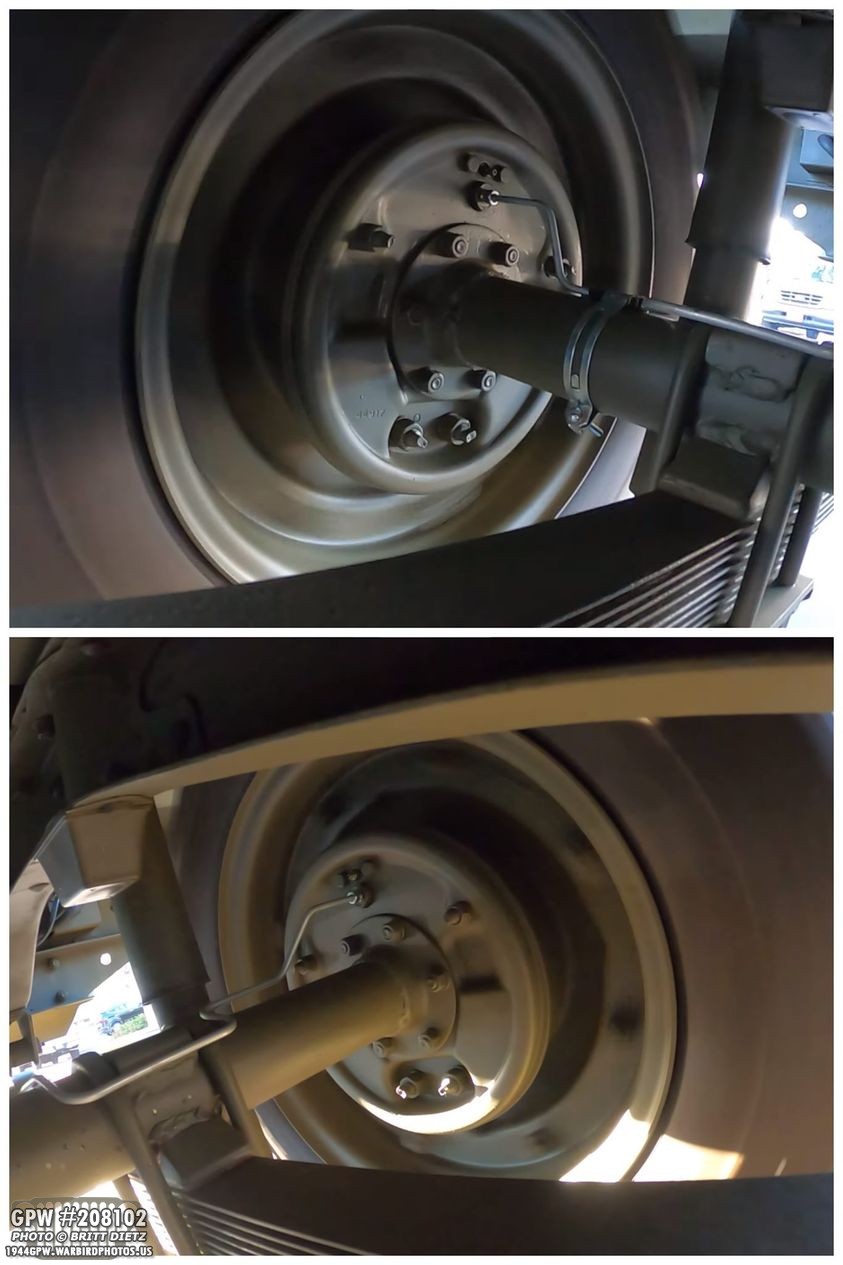

Here’s a screengrab from the driver’s side front wheel. You can watch the video here: https://www.youtube.com/watch?v=G9TtqpuRhWA

I only uploaded this front-wheel video (of the two) as in both videos it’s the same thing, you can’t hear the clackity sound at all. The chattering sound you hear is noisy valves on the engine.

But, the two rear axle videos, the clackity sound is LOUD as can be. Here area screen gabs of both videos. This probed, without a doubt, that the sound is coming from the rear axle. But, it sounds almost the same on both sides. What do you think? (And in the videos you can see that grease from the driveshaft flinging over everything)

Driver Rear Wheel: https://www.youtube.com/watch?v=ZIkGMTkvslI

Passenger Rear Wheel: https://www.youtube.com/watch?v=x63OqqtyPFA

So, what now? Well, there’s not much left to swap out or change. If you want to read about the full story, I posted it on G503 to get more ideas to try. See the thread here: https://forums.g503.com/viewtopic.php?f=4&t=323316

All that’s left to check is what I took from the rear axle… which would be the brake plates and drums. The wheels have been rotated and checked, new housing with new carrier/ring/pinion, driveshaft is fixed (and I used a different driveshaft to test). So it’s possible the sound is from the drums. So I’ll be taking them to a place to have them reamed to make sure they are round.

And that’s all I can do for now. I hope to have a friend (Jeep expert) come by in the next few days to drive the Jeep and tell me what he thinks of the sound. I don’t think going to all this work was for naught, as the first rear GPW axle had metal shavings in the housing after only 5 miles. Something was, for sure, wrong with it. So getting this other axle was a good idea. But trying to track down this elusive dragon has been a 4-month challenge. We’ll see what next week brings!

Till next week…