Rear Axle Wars – Episode 7: A New Hope

Rear Axle Wars – Episode 7: A New Hope

With the rear axle clackity issue eluding myself and many other trying to help me out, I’ve decided to go in a different direction and restore ANOTHER wartime GPW rear axle to replace the one I restored. Join me over the new few weeks as I restore and rebuild this axle and hopefully, solve the last major issue!

This week’s update will be a bit short again, but that’s about to change! Sadly, I haven’t been driving the Jeep much because I’m a bit nervous driving it all that much with the current rear axle issue. So let’s dive in…

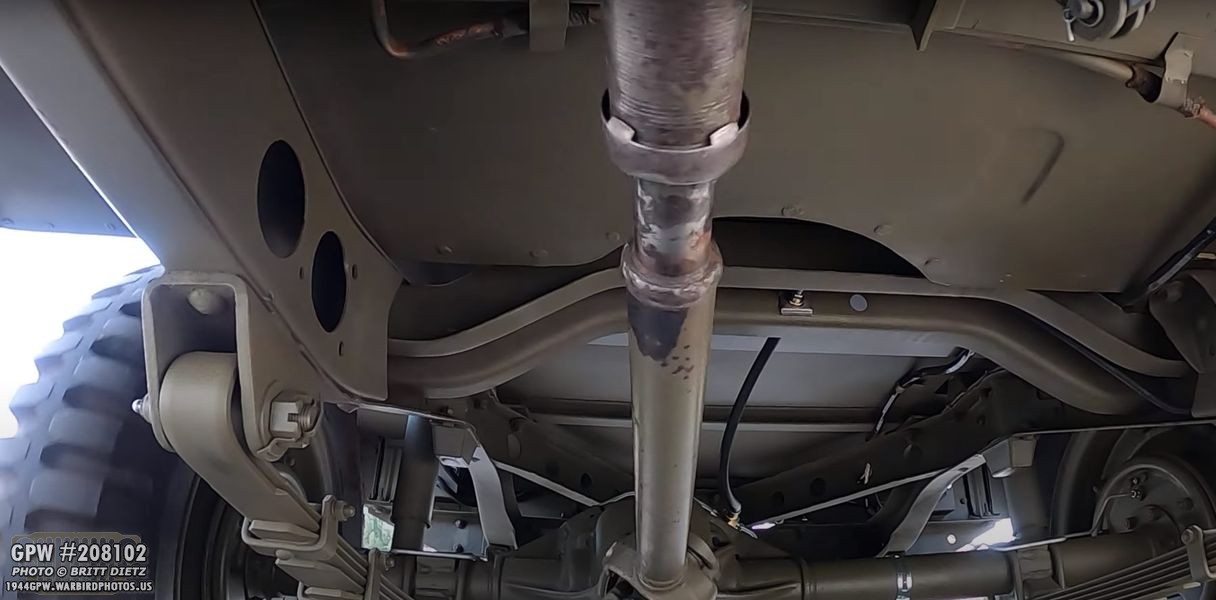

To catch everyone up to speed, this ‘Rear Axle war’ started after I replaced the CJ axles on my Jeep with wartime GPW ones. There suddenly was a strange clackity sound coming from underneath, and metal shavings in the rear axle housing. Last week I bought a GoPro and mounted it under the Jeep (shown here) as I was driving around the street. It revealed that 1) the rear drive shaft is bent, and has a wobble, and 2) the sound is for sure coming from the rear of the Jeep.

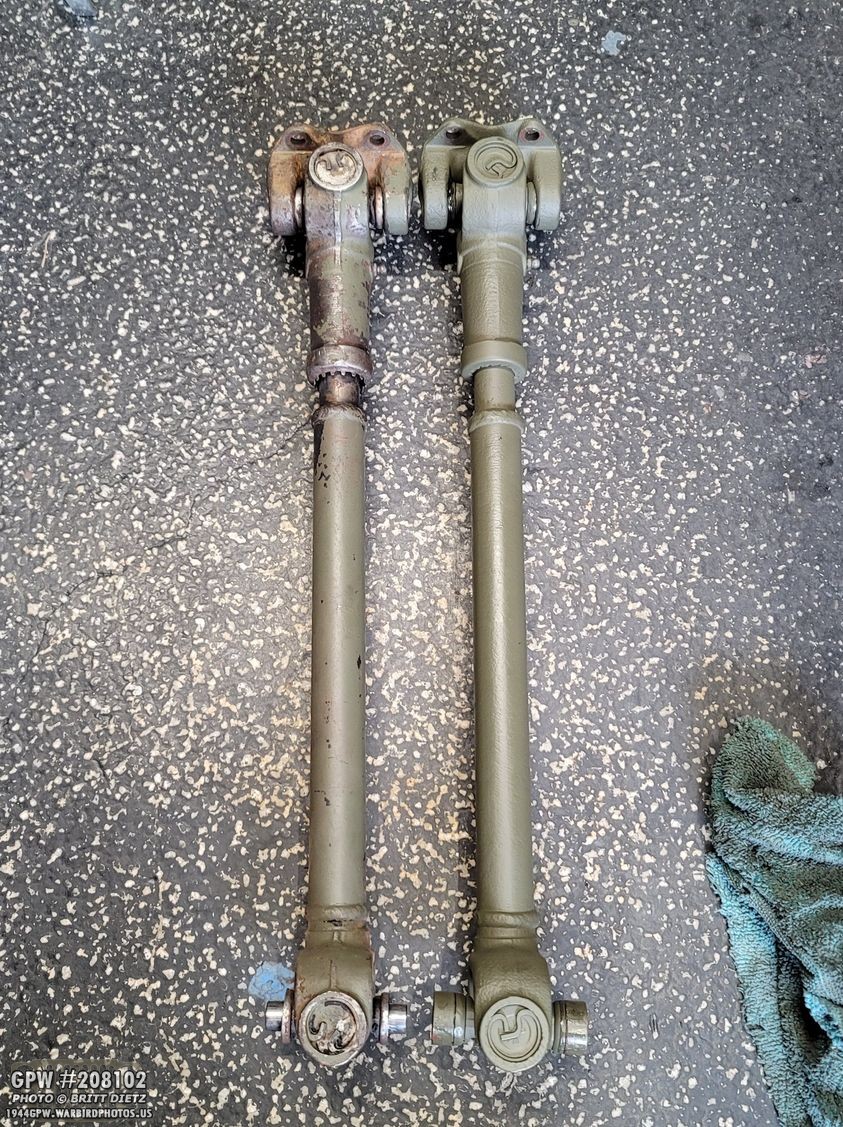

After posting about the clackity issue on G503, the common consensus was that the rear driveshaft wobble was the cause of the sound. I knew this wasn’t it, but just to prove that I managed to get ahold of a spare rear driveshaft from Matthew Caffrey, shown here. I brought it home, cleaned up the grease, and gave it a good bath.

Taking off my rear driveshaft (on the right), I can’t see a difference right off the bat, but the big test would be to see if this spare driveshaft wobbles. If the sound went away, I’d be surprised. But it was more of a test to make sure there wasn’t something wrong with the rear axle yoke or e-brake companion flange.

So, I went ahead and got that spare driveshaft mounted into the Jeep. There’s no mistaking it as my driveshaft! Ha ha.

Side note – That’s the GoPro camera mount on the bottom of the e-brake drum. You can also see the gobs of grease that this temp driveshaft have flung onto the bottom of the tub. DOH! I’ll have to clean that.

I mounted a GoPro again under the Jeep (screenshot here) and took it for a drive. It was perfectly straight, no wobble whatsoever. And the clackity sound? Still there as expected. That tells me that it is definitively the rear axle housing causing the sound. And it also proves my driveshaft is slightly bent.

So, what about my bent driveshaft (shown here from earlier this year when I stripped the paint)? I’m going to take it to a local driveline shop and see if they can straighten it out. To get a take-off original driveshaft is about $300 or more, and a repro driveshaft is about $200. I think I can get my original straightened for about $100 or less if they can do it. I’ll update this next week when I drop it off at the place.

So, that takes us back to this rear axle. To provide some context for those who haven’t followed along, when I got this rear axle (free from a fellow G503 member), I discovered there was a terribly violent spider gear explosion that damaged the pinion, ring, carrier, and housing (cracking it). The crack was fixed, and a new carrier, ring, pinion, spider gears, etc were added. But the theory now is that the explosion was so violent, it actually might have tweaked the housing in a way it’s not usable anymore. Continuing to chase this issue could very well be for nothing. So what now then?

How about I get another GPW rear axle? Yup, thanks to Roger Smith, I drove up to Lancaster and picked up another original GPW axle. This axle is in better shape, but needs a full restoration and rebuild. Thankfully, I just did all this once before earlier this year!

The carrier was pretty stuck, however, with a lot of gunk jamming the bearings. No worries about that, however, as I’ll be using whatever I need from the ‘bad’ rear axle since a lot of the parts are pretty much brand new having been installed just three months ago. The big question is, can I use this Ring and Pinion once I clean it up?

Looking at the caps for the carrier bearings, They have the proper GPW markings. One thing I want to point out for those who don’t know, is they mark these caps with a mark that matches the same orientation so you can’t mistake which side and which way you put these caps on. You can see this upsidedown 7 that matches up on this one…

And on the other side, there’s a sideways 7. The 7 on the bearing cap is next to the E.

This axle is chock-full of stamps, so so so many stamps all over the axle. More than I’ve ever seen on an axle. You can see one of them there. I’ll go over all these stamps a bit later in this update.

Diving in, I unscrewed the caps and took them off. I had to use a breaker bar to get the screws to come out, but they went relatively easy. I then tried to get the carrier out… it wouldn’t budge. It was stuck in there REALLY good. I tried for over an hour to use a breaker bar to hammer the carrier out, those bearing races didn’t move 1mm. I tried literally everything, and without a housing spreader ($200+), I was out of options.

So, I had to cut the races. I used a Dremel to make cuts being incredibly careful not hit the carrier or the housing. It took a LONG time to cut through them, but I finally got it. And, amazingly enough, I didn’t hit the carrier or the housing at all! I’m replacing the bearings/races anyway, so I wasn’t worried about ruining these.

With the races cut, the carrier nearly fell right out no problem! So far, it’s looking like I might be able to use this Ring and carrier!

I then removed the yoke and drove out the pinion. Here’s a look inside the housing. Looks pretty good.

Going back to the carrier, I wanted to inspect the markings to see if it’s a GPW ring…

Looking at the backside, Only two of the bolts have F stamps, and three of the lock clips have F stamps.

I removed the bolts and the clips (had to use an impact gun to replace the bolts, they appear to have never been removed, they were in there REALLY good).

I was then able to use a rubber hammer to rock the ring off the carrier.

The ring is dated January 26, 1945. That’s 7 months to the day after the DOD of my Jeep.

And there’s the GPW 4210 number.

And the F mark, with the inspector’s engraving… looks like a 4, but I can’t make out the second number/letter.

Then an F27, along with another engraved number of 7937.

Finally, a 39 and slash? and an 8 number, which is the teeth ratio with the pinion… 39/8. Same as the axle ratio tag. Overall, the ring isn’t in terrible shape, I could use it.

Looking at the pinion, there’s the matching 7937 number that was engraved by hand on the ring. Unfortunately, the pinion is not in good shape. While the teeth are not horribly worn, there’s some major pitting on the teeth. 🙁

On the pinion, there’s a Ford stamp (you can just barely make out the ord), a 2, a 44 (1944?) and a possible date… but that seems to be WAY too early. It almost looks like 1-8-39. As far as I know, the Jeep wasn’t even built in 1939. So not sure about that date.

I’m a bit disappointed the pinion isn’t in better shape, but… as long as the ‘bad’ rear axle hasn’t really worn down the NOS GPW ring and pinion I put in there, I’ll just use those instead.

The pinion spacer, however, I’ll use it as it’s in perfect shape. The NOS gpw ring and pinion set I got for the ‘bad’ axle didn’t come with one, so I had to use the one from the original spide gear exploded pinion which is in rough shape.

On Thursday I finally took the axle out to the yard to remove the red oxide paint. I could have kept this paint, but 1) it was rather dirty, and 2) I wanted to search for markings.

A couple hours later and several sized wire wheels, here’s how it looks. Mostly cleared of paint.

Whatever red oxide primer paint was on this axle was incredibly hard to wire wheel off. It would turn into a heavy powder that would then stick back to the axle and get in all the little crevasses.

I ended up going back over everything with a nylon wire wheel, which helped to lift the now ‘powder’ red oxide out of the grooves and clean up the metal further. GOOD ENOUGH. There’s still some of the paint in the hard to reach places, but the dirt is gone and I’m just going to paint over it anyway.

And a look at the other side. What you don’t see is my gloves, sleeves, shirt, etc totally covered with this red oxide powder. Thankfully I always wear a breather mask with goggles. So, now that I’m done… let’s hunt for markings!

There’s a nice full Ford mark on one of the axle feet with a 2.

The other side foot has a single F with a 2.

On the main housing, there’s a 23. I’d imagine for Dana 23.

Then there’s a GP4025, the standard for GPW axles.

Then we get into the very odd markings. First, this interesting grouping! I’ve never seen something like this before. It almost looks like an ordnance flaming bomb with a K and D… then a 1 in a half-circle, and possibly HQ? One theory is that this was rebuilt by Ordnance deport for 1st HQ?

On one of the ‘donuts’, we have a ton of stamps. I can’t make heads or tails of any of this. Thoughts?

Another interesting stamping is this A and 65 70. One person mentioned this looks like British markings, meaning this axle has been to the UK. No idea what it means though.

On the other donut, there’s a single D.

On the U bolt spacer on one side, there’s a partial A stamped.

On the top lip, there’s something stamped in a circle, possibly a T?

On the other U bolt spacer, there’s there are two other things stamped, but they are only partial and I can’t tell what they are.

There’s a K on the cover surface.

On the bottom of one of the feet, there are two 116 in circles and possibly a part of a third one?

On the bottom lip of the housing, there’s a large B partially stamped. There’s SO much stamping!

On the left brake plate flange, there’s a circle with something stamped in it, but I can’t make out what. I’ve never seen so many stamps on a single axle.

Moving on finally, I went to work removing the final bearing, oil seal, and the inner pinion race. I used a punch to carefully rock out the race going back and forth (there’s a slot cut into the housing to do this). That pushed out the oil seal, bearing, and that race. I then flipped the axle over and did the same to the race which you can see in this photo.

Here’s the bearing, the two races, the oil seal, and a HECK of a lot of shims.

Housing is now clear of everything! I’ll clean the inside over the weekend with a degreaser and powerwash it out.

So that wraps up this update! Over the weekend, I’ll be starting the process to take off the ‘bad’ axle, and pillage parts from it to put in this new axle. I hope to begin the painting process for the new axe this coming week as well. All in all, I expect this new axle to take about a week and a half until it’s ready to rock under the Jeep.

Till next week…